- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

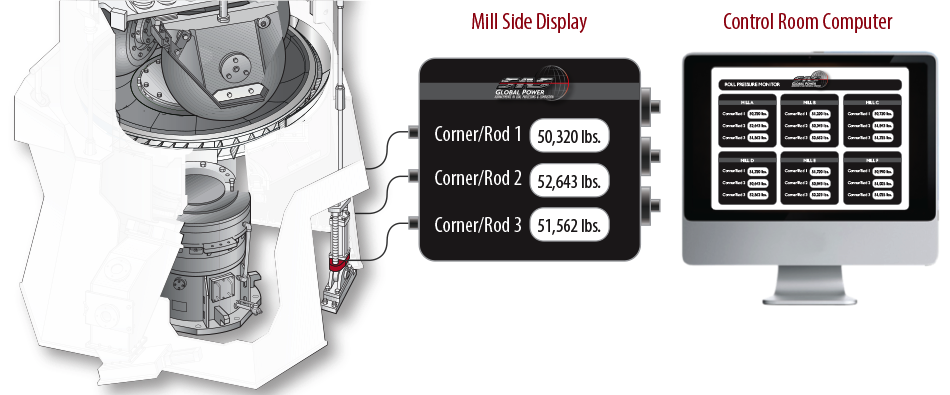

Grinding Pressure Monitor System - MPS Series Mill Modernization

Proper grinding pressure in your MPS Mill is very important in order to maintain capacity and proper fineness. Ideally, your grinding pressure should change with load. As the load goes up, so should the grinding pressure.

KEY BENEFITS:

- Improve and Monitor Capacity

- Improve and Monitor Fineness

- Calibrate pressure for fineness to control capacity amd mill DP

- Konw when grinding surfaces are wearing

- Konw when spring degradation is taking place

- Be able to identify when tramp iron is in the mill

- Balance the load evenly on the main baerings

Do you know what your actual real-time grinding pressure is? Would you like to?

If so, the SAS Patented Grinding Pressure Monitor System is your answer. This device is engineeried to messure the grinding pressure at each of the grinding locations within a vertical mill. This is accomplished with the use of load cells. The information is shown on a local display and/or in the control room.

Example System for a MPS Style Mill Shown

Copyright © 2024 SAS Global Corporation | All Rights Reserved