- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

SAS Global Patented In-Line Diffuser | Burner Diffuser

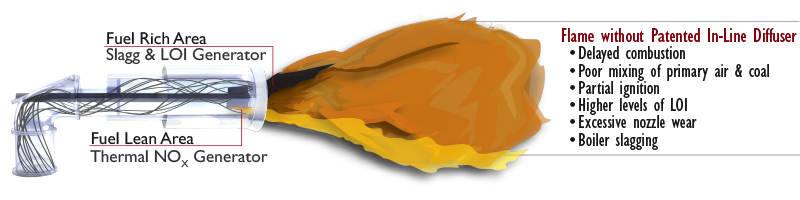

Reduce NOX, LOI, Slagging, and Increase Burner Tip Life

The Patented SAS Global In-Line Diffuser was designed to eliminate the coal ribboning and provide a homogeneous mixture of fuel and air flowing to the boiler. The SAS In-Line Diffuser is installed just after the last elbow or connection leading to the burner pipe. Every type of burner manufactured will benefit from the In-Line Diffuser’s ability to transform coal ribbons into a homogeneous flow to the boiler!

Wall Fired Burner Diagram without Patented In-Line Diffuser

Wall Fired Burner Diagram without Patented In-Line Diffuser

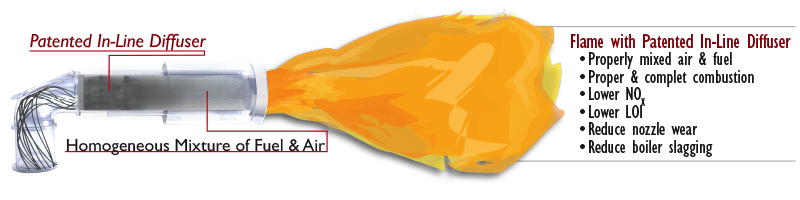

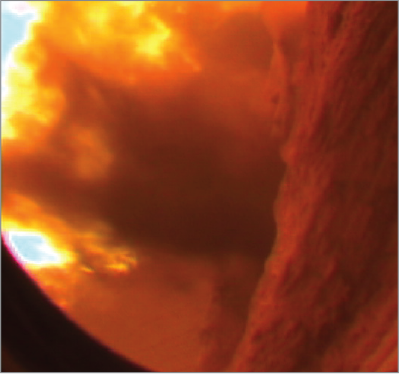

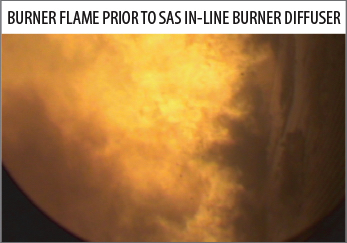

Burner A2 Pre ILD Installation

Visual Signs of Poor Combustion

- Flame detachment

- Areas of very heavy fuel

- Slagging around the burner

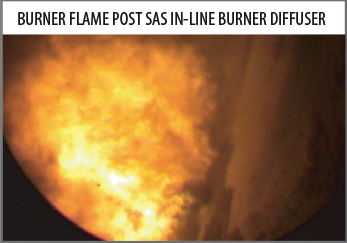

Burner A2 Post ILD Installation

Visual Signs of Improved Combustion

- Attached to burner face

- Bright flame

- Proper fuel mixture

- Improved burner plume

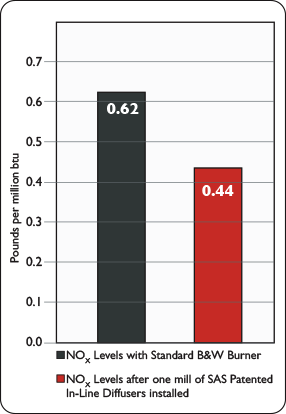

CASE HISTORY: Dramatic Reduction In NOx Levels

A dramatic improvement in NOX emissions was just achieved by utilizing the SAS Global Power Patented In-Line Diffuser.

SAS In-Line Diffusers were installed on one mill, which is a third of the Utilities B&W Wall Fired Boiler running at full load. When this mill was brought back online the NOX levels plummeted almost 50% from a base line level of .62. Due to operational concerns, airflows were adjusted to bring NOX back to .44! The CO and O2 levels also improved.

The Utility was amazed with the lower emission levels and couldn’t believe the improved appearance of the flames.

The remaining burners are now scheduled to be upgraded with SAS Patented In-Line Diffusers.

This image indicates delayed combustion due to the poor mixing of primary air and coal. The coal has to travel much farther into the boiler before it mixes with air to start the combustion process. Increased NOx Levels, LOI and boiler slagging are symptomatic with this condition.

This image indicates a clean burn which happens when air and coal are properly mixed. The entire outer area of the flame surrounds the contained inner fuel and air. This type of condition allows for controlling NOx with the secondary air and over fire. Fuel bound Nitrogen can be released from inside the flame and form N2 and not NOX (Prompt NOX).

Copyright © 2024 SAS Global Corporation | All Rights Reserved