- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

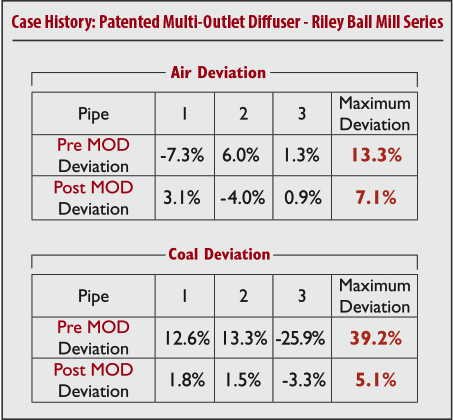

Patented Multi-Outlet Diffuser / Patent Pending Conical Fuel Particulate Diffuser: Fuel Pipe Balance Remote Classifer Series

Improve Balance Pipe to Pipe Fuel Flows • Improve Air / Fuel Ratios • Reduce Emissions • Improve Combustion

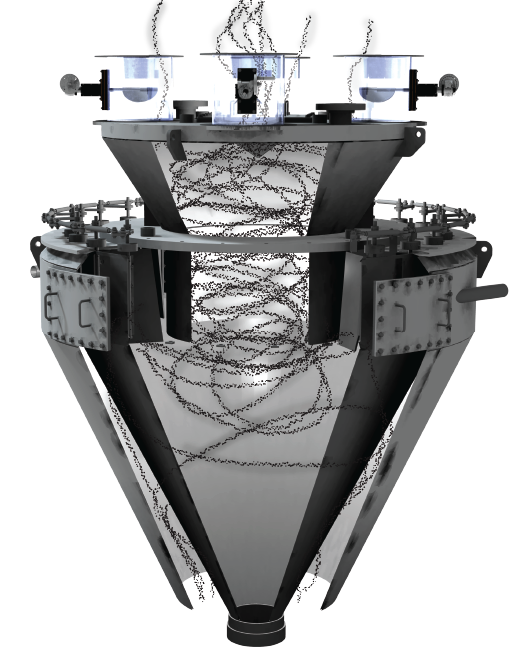

Transform your Remote Classifier from this...

Coal ribboning, or roping, naturally occurs inside of the remote classifier due to traveling through the mill piping and classifier system. If these ribbons of heavy fuel are allowed to continue thru the upper turret section, they will cause very unbalanced air/fuel ratios and a high deviation of fuel distribution across the discharge pipes.

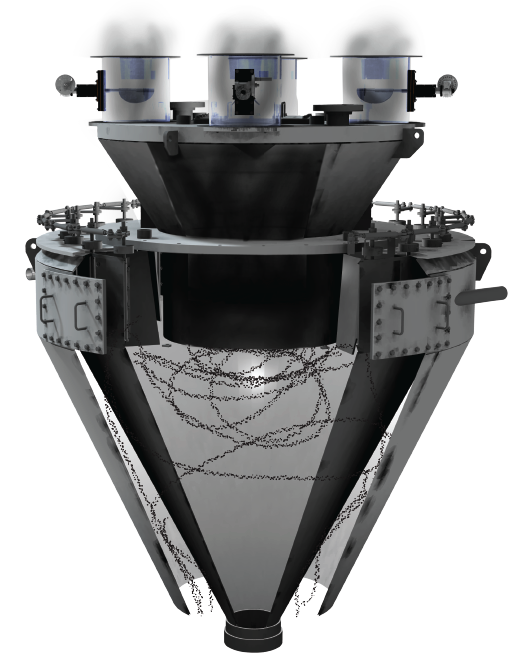

... to this with the SAS Multi-Outlet Diffuser

The SAS Multi-Outlet Diffuser breaks up these naturally occurring Coal ribbons and creates a homogeneous mixture of fuel and air exiting the top of the Pulverizer and entering the fuel pipes.

SAS Global has learned through extensive modeling, field research, and testing that to correct fuel pipe imbalance the problem must be dealt with at the source – as the coal exits the remote classifier. SAS has developed the Multi-Outlet Diffuser to deal with this challenge. The SAS Multi-Outlet Diffuser system mixes the pulverized coal and air into a homogeneous mixture as it exits the remote classifier system and enters the individual fuel pipes. A significant improvement in air to fuel ratio between all the fuel piping now allows for the proper usage of an orificing system, if needed, to match the fuel pipe velocities.

Copyright © 2024 SAS Global Corporation | All Rights Reserved