- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

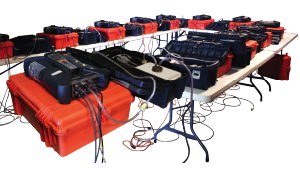

Real-Time Multi-Stream Combustion Analyzer

The MSCA can analyze up to sixteen (16) flue gas streams simultaneously. This approach reduces the test duration by a factor sixteen. Further, the MSCA instrument maintains its accuracy, so no pre and post test calibration is required. In addition, the data is recorded in real time using a laptop computer, and custom software translates the data into results within a few minutes of the completion of the test. This short duration helps to better ensure all data and results are representative of the boiler’s firing conditions without the influence of slagging and fouling on emissions, such as NOX.

Another benefit is the ability to determine the cause-and-effect relationships of burner tuning almost in real time. The MSCA will allow the real time monitoring of a duct’s emissions while a plant representative makes operating changes, such as burner air register settings.

Hence, the impact of only one (1) burner air register change can be visualized on the entire boiler within 3-5 minutes instead of hours with traditional sampling and analysis.

Advantages:

- More flexibility in operation since the boiler is not always locked at one firing condition

- Increased time for sootblowing, load changes and other necessary operations

- Increased variables can be studied within a given time constraint

- Greater confidence in the data and results since operational variables (slagging and fouling) are reduced

- Reduced labor from the utility

- Reduced contractor labor, per diem and equipment rental fees

EXAMPLE DATA

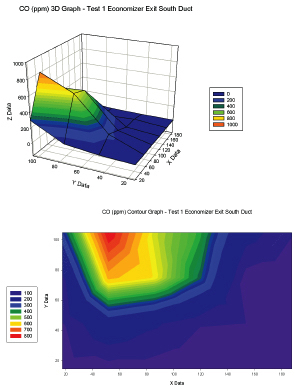

Economizer Exit CO (ppm)

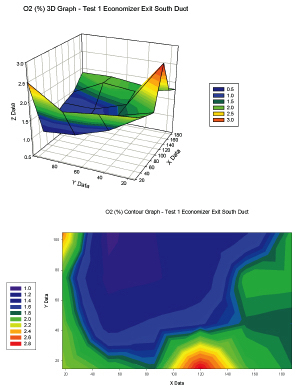

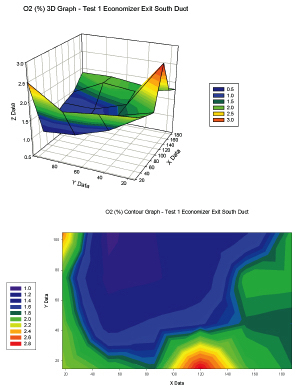

Economizer Exit O2 (ppm)

Economizer Exit NO (ppm)