- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

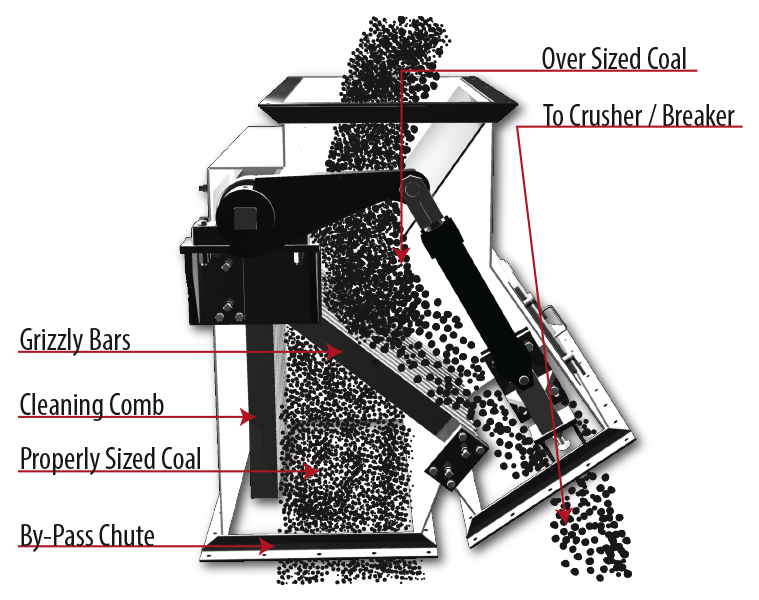

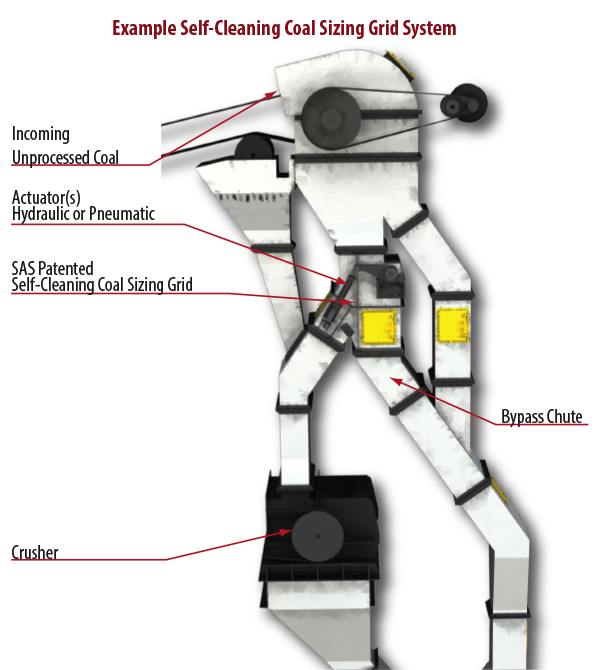

Patented Self-Cleaning Coal Sizing Grid

Increase the life of your crusher while reducing amperage usage

Equipment wear is prevalent and constant in all coal crushing or sizing operations. Typically all coal being transported to the silo passes through a crusher to maintain a consistent and acceptable size. Studies show 80% to 90% of the coal being fed through the crusher is already at an acceptable size. This adds lots of unnecessary wear and amperage usage.

The Patented SAS Self-Cleaning Coal Sizing Grid System is designed to allow maximum material of acceptable size to bypass the crushing operation. The results are a drastic reduction in wear and tear on the crusher components, immediate savings in amperage required for running crusher motors, and increased feed rate capacity.

Features and Benefits of the SAS Self-Cleaning Coal Sizing Grid

- Reduce wear and tear on crusher

- Reduce frequency of crusher rebuilds

- Reduce amperage usage

- Increase throughput