- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

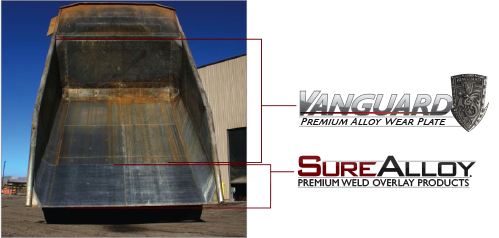

Performance Smooth Mining Haul Truck Bed Wear Resistant Liner Systems

Increase Service Life, Reduce Carry Back, Reduce Unloading Cycle Times, Reduce Hydraulic Wear

SAS Global Corporation has developed an engineered truck bed liner package system that provides significant cost savings and return on investment. Although the package is designed to greatly improve the wear life of the truck bed. Knowledge gained from computer modeling and actual field-testing has shown that our package substantially increases structural strength of the bed and greatly enhances performance in operations.

Proven Performance Benefits:

- Engineered for a completely clean dump every cycle

- Material dumps from the bed by the time bed is raised 70%

- Reduction in Hydraulic Wear and Failure

- Reduced Installation Time

- Reduced Weight

- Easy to Maintain

Tail Section Liner Still Going Strong After 10 Years In Service

CAT 793D SAS Global Premium Truck Bed Liner Case History

A large hard rock gold mining facility recently performed a scheduled inspection and maintenance on one of their CAT 793D haul trucks. This bed was removed from service due to the alloy steel ahead of the SA1750CR Premium Chromium Carbide Overlay Plate tail section needing to be replaced. This truck had been utilizing the same SAS Premium Liner System for 10 years!

During this maintenance, the SAS Global SA1750CR Tail Section Liner only had a few hot spots. These simply required hand overlay via hardface welding, which was done in the field. The back 90" SA1750CR liner was then released back into production for a second time.

The thickness inspection revealed the SA1750CR Tail Section only lost 0.187” (just about half the starting thickness), and the wall liners only show very slight signs of wear after 65,000 hours of service over the last 10 years!

Shown below is a SAS liner package installed in a CAT 793D truck bed. This liner has been in service for over 1.5 years at a large Gold Mine in Nevada. The Gold Mine expects this SAS Global Liner to last 4 plus years. The liners from a competitor were lasting only 16 months.

SA2000® is a specially formulated complex carbide overlay plate designed to generate a high concentration of small primary carbides greatly improving wear resistance over conventional chromium carbide alloys. The refined microstructure containing harder complex carbides provides greater wear resistance and improved toughness. The inert refractory carbides present also increase the temperature resistance and corrosion resistance. Up to double the service life of standard chromium carbide overlay plate.

SA1750CR® is a Premium Chromium Carbide Overlay Plate consisting of a Hypereutectic Matrix with 50-60% Chromium Carbides metallurgically fused to an appropriate steel substrate. This large amount of hard chromium carbides allows SA1750CR to thrive in environments of extremely high abrasion.

SA6000® is the new future of overlay wear plate. The patented microstructure of SA6000 is highly refined with tightly packed complex carbides. This fine grain microstructure reduces the propagation of cracks, which results in not only superior protection from abrasion, but also unheard of impact resistance!

SA-MCCTM was developed to satisfy the various application needs of our customers. SA-MCC Multiple Complex Overlays can be custom blended to provide material characteristics needed for specific wear resistivity. For example, if the application requires increased impact resistance and temperature rating, the blend of complex carbides would have higher levels of Molybdenum and Niobium.

SAS Global Engineers a smooth surface finish on all SureAlloy® Premium Weld Overlay Products. The standard SureAlloy® surface finish can be blanchard ground to provide an even lower coefficient of friction for applications with heavy material hang-up issues. This premium surface is known as RapidFlow® Premium Surface Carbide Overlay Plate. The surface is ground and polished to a 0.2 Ra Micro-Meters finish. This finish is smoother than a stainless steel 304 with 2B finish.