- HOME

- Products

- Wear Resistant Materials

- Coal-Fired Power Generation Products and Solutions

- Mining Industry Products and Solutions

- Cement Industry Products and Solutions

- Steel Industry Products and Solutions

- Asphalt Industry Products and Solutions

- Aggregate Industry Products and Solutions

- Dredging Industry Products and Solutions

- Foundry Industry Products and Solutions

- Metal Recycling Industry Products and Solutions

- Pulp and Paper Industry Products and Solutions

- Sugar Cane Processing Industry Products and Solutions

- Services

- Contact

- About

- News

- Careers

- Blog

- Terms

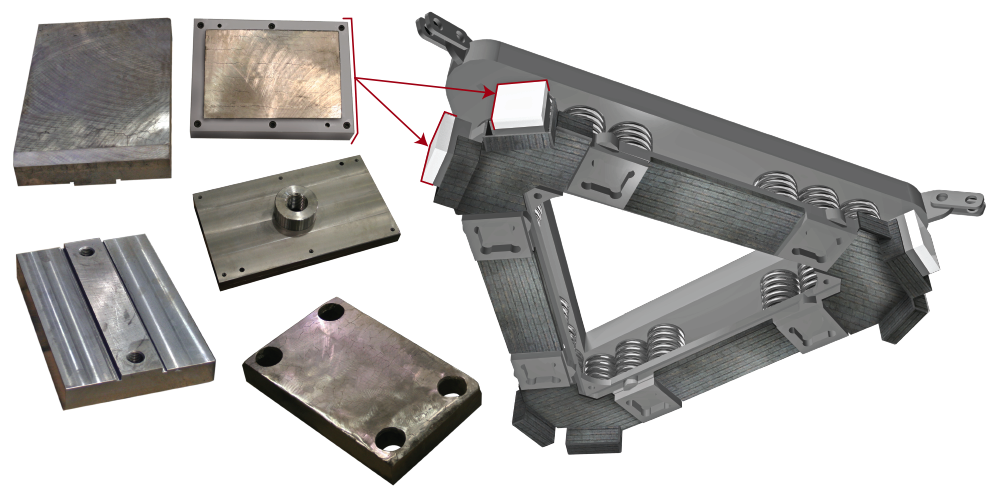

Pressure Frame Wear Plates and SAS Protection System - MPS Series Mill Modernization

Fabricated from Premium Wear Resistant Materials to Provide Maxium Protection and Service Life

Pressure Frame Wear Plates

SAS Global Premium Pressure Frame Wear Plates are custom manufactured to meet your specifications and service life goals. SAS Global has many premium wear resistant material options to provide you with the best possible solution.

Abrasion Resistant Material Options:

SAS Pressure Frame Wear Protection System

The pressure frame in your MPS Pulverizer is a vital component that is exposed to erosion from the pulverized coal making its way up to the classifier. The pressure frame is a very labor intensive component to remove and replace. So, why not give it the best protection available?

Shown above are images of wear found on a typical MPS Pressure Frame.

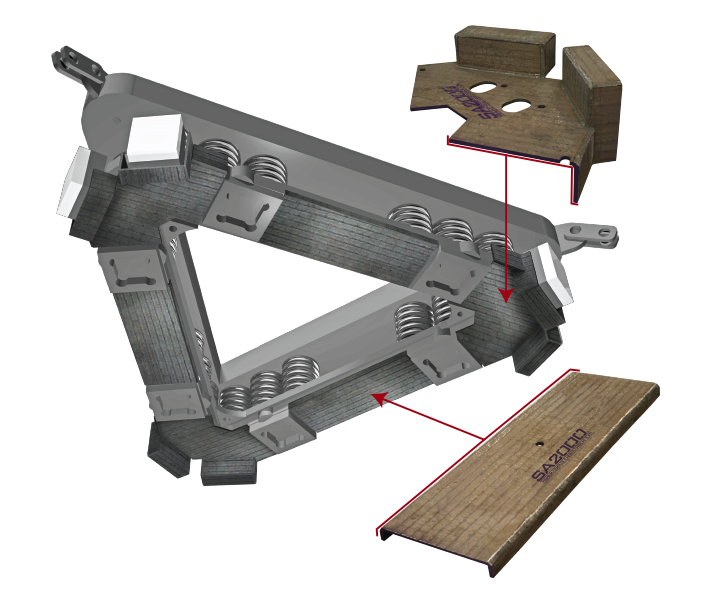

Shown above is a SAS Pressure Frame Liner System installed. The SAS Liner System shown is fabricated from SureAlloy® Premium Carbide Overlay Plate for maximum protection.

SAS Pressure Frame Wear Protection System shown above fabricated from SA2000 Premium Complex Carbide Overlay Plate.

Can also be fabricated from:

SA1750CR Premium Chromium Carbide Overlay Plate

SA6000 Patented Mircostructure Complex Carbide Overlay Plate

SA6000® is the new future of overlay wear plate. The patented microstructure of SA6000 is highly refined with tightly packed complex carbides. This fine grain microstructure reduces the propagation of cracks, which results in not only superior protection from abrasion, but also unheard of impact resistance!

SA2000® is a specially formulated complex carbide overlay plate designed to generate a high concentration of small primary carbides greatly improving wear resistance over conventional chromium carbide alloys. The refined microstructure containing harder complex carbides provides greater wear resistance and improved toughness. The inert refractory carbides present also increase the temperature resistance and corrosion resistance. Up to double the service life of standard chromium carbide overlay plate.

SA1750CR® is a Premium Chromium Carbide Overlay Plate consisting of a Hypereutectic Matrix with 50-60% Chromium Carbides metallurgically fused to an appropriate steel substrate. This large amount of hard chromium carbides allows SA1750CR to thrive in environments of extremely high abrasion.

Copyright © 2024 SAS Global Corporation | All Rights Reserved